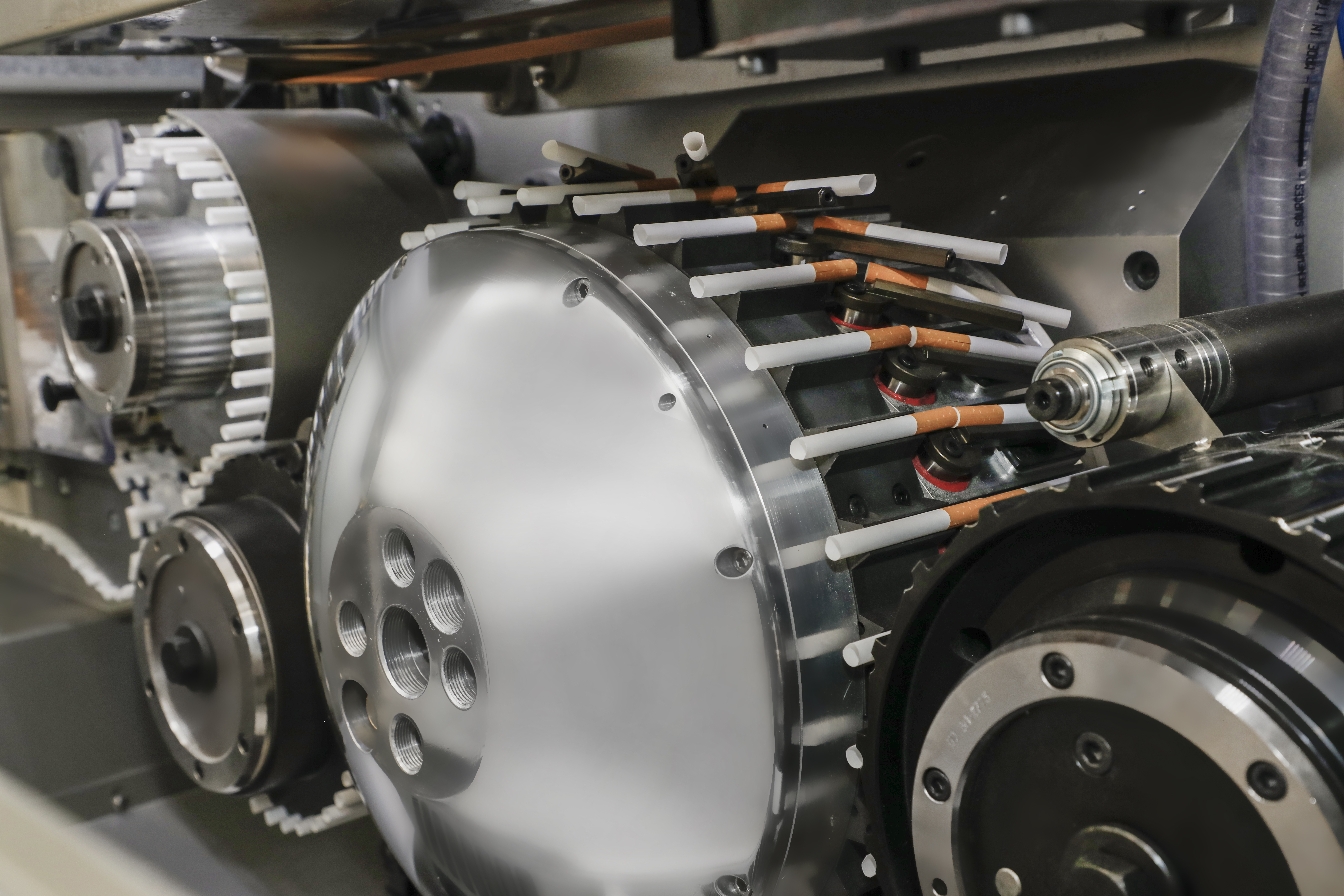

Meet our brand-new making and packing line for tubes!

SASIB top-selling product has been renovated with a series of original features, most notable of all the maximum tubes production, which has been boosted up to 8,000 tubes per minute in the maker section (SFT-M).

This improvement has been achieved thanks to the extension of the sealer area; furthermore, the cork paper cutting system has been redesigned in order to match the one from the SMK. The spider was also upgraded to the SMK one; this is because the successful SASIB maker SMK has been indeed proved to be the right model for a significant number of enhancements to the SFT line.

SASIB SMK inspired some updates in the drums as well; today, these allow a quicker size change of the filter length.

The hopper and the filter descent drum have also been renovated: they now help a faster regulation, and a smoother operation.

All these changes brought the SFT-M production to a whole new level of stability and efficiency.

The packer section (SFT-P) was modernized as well.

In addition to the flexibility of size change of the boxes, which had already been introduced, the axes are now electronically regulated. In this way, the details of the size change can be set on the PLC, and are automatically transferred onto the machine, without any need to adjust the components manually. The operation can last half an hour at most, down to 10 minutes if performed by an expert operator.

As a whole, this latest edition of the line offers increased reliability at higher speeds, and an improved and faster management of the size changes.