Rebuilding & Refurbishment

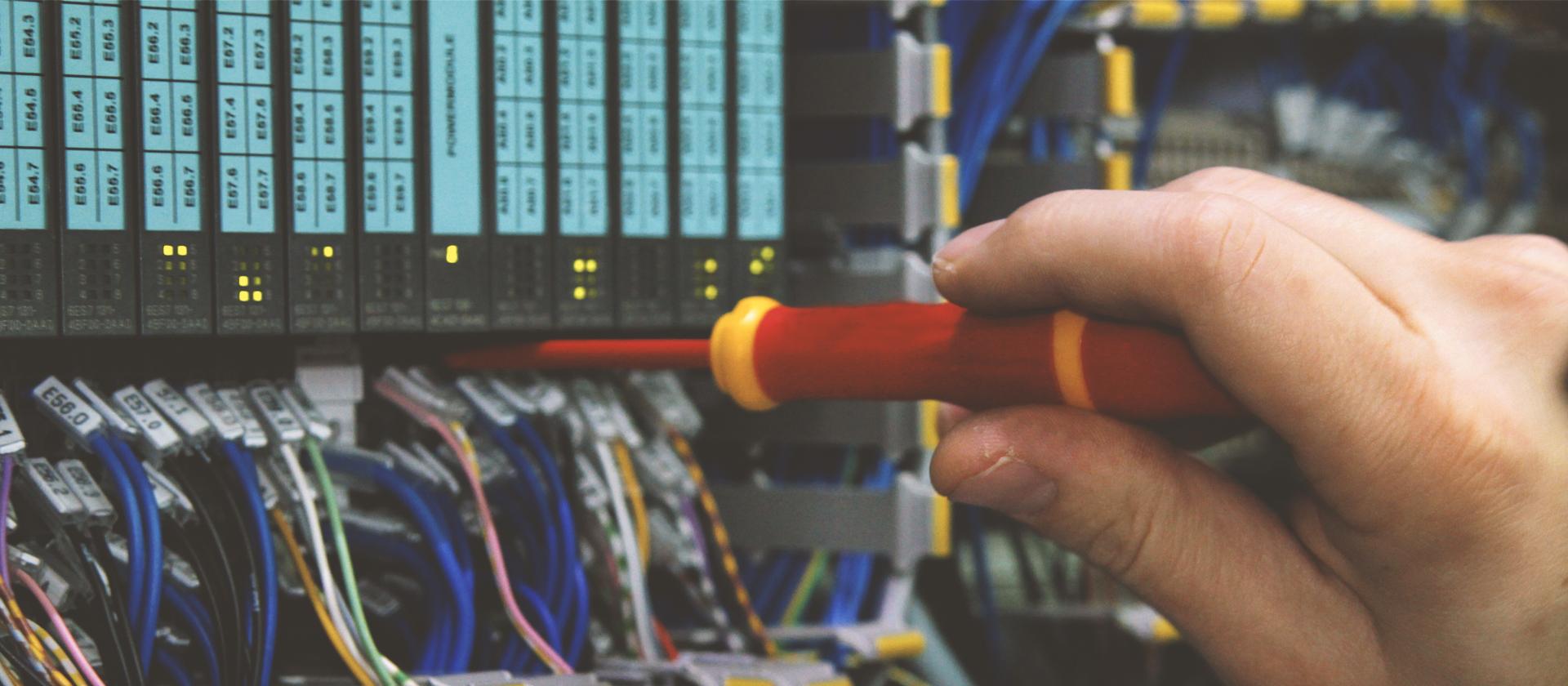

SASIB offers rebuilding service including installation, line protocol and, when requested, staff training by SASIB technicians. The service includes complete machine disassembly, replacement of all worn parts, raising the machine to top quality performance standards and incorporating the latest technical innovations to provide a completely renewed machine. All electrical parts are also removed and replaced with a new PLC system, motors, sensors, and new operator interface with touch-screen display.

At the end of the process machines are tested following overhaul and rebuilding. Complete technical documentation such as user manual and spare parts catalogue are provided.